Estimating the service life of the material helps to select the suitable material, optimizing and performance evaluation for a particular application.

KEY INSIGHTS

- The report elaborates the property of thermal endurance of a material.

- The report provides the detailed step by step process to determine the lifetime of the polymer sample using Arrhenius equation.

- A case study has also been provided.

BULLET POINTS

- Plotting the graph of any change in the physical or chemical property of the material across the temperature range is a time consuming process. The process becomes more tedious when more than one sample needs to be studied.

- The presented report details the method to evaluate and plot the lifetime of any polymer material at a temperature range using the data obtained from DSC or TGA.

KEYWORDS

Activation energy, Arrhenius Equation, Lifetime prediction, Polymer degradation

DETAILED REPORT

WHY WE NEED TO DETERMINE THERMAL ENDRANCE?

Thermal endurance is a vital property of any material as it helps

- In predicting the useful life of any material which involves the investigation of the isothermal and non-isothermal degradation at relatively high temperatures in inert or oxidative atmospheres [1].

- In design optimisation and performance evaluation requires knowledge of endurance under stresses which has, at present, been investigated but scarcely.

- In determining the suitability of a particular material for the intended purpose [2].

- To evaluate the effect or efficiency of prodegradant agent [3].

HOW TO DETERMINE THERMAL ENDURANCE?

The following Figure 1 shows step by step method to determine the useful life time of the material using the data obtained from TGA. The data can be used for short-term thermal endurance characterization of polymer materials.

Figure 1: Step by step method to determine lifetime of the sample using TGA data and Arrhenius equation.

CASE STUDY FROM THE LITERATURE

Xian et. al. [4] studied the thermal decomposition kinetics of core-shell structured wood-plastic composite material with white mud loading in the shell. The thermal decomposition was studied using TGA data performed at varying heating rates i.e. 10, 20, 30 and 40OC/min from ambient temperature to 700OC. The white mud loading in the range of 0% to 25% in the shell layer was carried out. TGA was performed for all the samples at different heating rates and the data of T5 (temperature at which the material loses 5% of its weight) is given in the said research paper.

We will focus on the data obtained for the sample without any white mud loading. The following Table 1 gives the values of T5

Table 1: TGA data adapted from the reference.

| Heating rate | T5 (OC) |

| 10 | 312.6 |

| 20 | 327.1 |

| 30 | 333.5 |

| 40 | 349.8 |

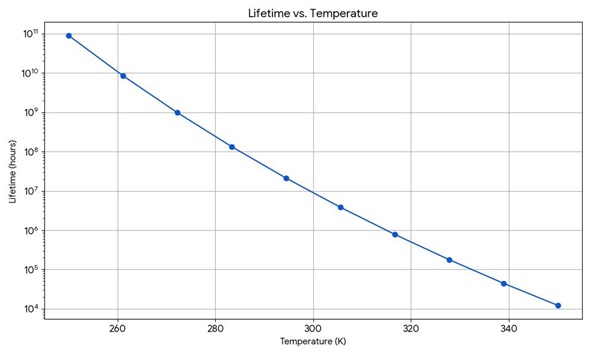

Plotting the Arrhenius graph from the above data as log (heating rate) vs. reciprocal of absolute temperature (K) gives the following values:

Activation energy (Ea) as 115 kJ/mol

Pre-exponential factor (A) = 1.99 * 1011 min-1

The lifetime of the sample can be determined at various temperatures using the following equation (1)

Tf = A*e(-Ea/RT) (1)

The graphical representation for the lifetime is as follows:

IMPORTANT NOTES

The effect of diffusion rate of oxygen into the bulk sample depends on the temperature and the geometry of the sample. The limited supply of oxygen in the interior of the specimens because of too many chemical reactions cause a lack of oxygen within the material, leading to the evolution of spatial dependent degradation ones [5].

The standard procedure is to study a certain property of the material in a certain temperature range and then plot it as ln k and the reciprocal of the absolute temperature (1/T) to allow the extrapolation to lower or higher temperatures. However, the procedure may fail when too large a temperature interval is examined. Consequently, the standard requires not only appropriate monitored parameters but also the proper selection of the end-point criterion. The experimental parameters and end-point criteria should correspond to the ageing, and a sufficiently sensitive measurement method should be applied.

Isothermal differential calorimetry and isothermal thermogravimetric analysis were applied for the short-term thermal endurance characterization of polymers. The two analytical techniques provide comparable results (in good agreement with those obtained by the conventional procedure) if they are applied to polymers, like nearly pure polyolefins, for which oxidation is the largely prevailing degradation mechanism. In materials, which are heavily filled and/or contain additives like flame retardants, other reactions can superimpose and prevail on oxidation; for these materials, only isothermal thermogravimetric analysis provides satisfactory results [6,7].

The Arrhenius presentation may be used to verify the kinetic modelling of the experimental results and to check the precision of the individual measurements. The data points should fit closely to the (fitted) straight line. If the data points are curved, failure to fit the model is indicated. If the data is scattered, additional experiments may be needed to improve the results [8,9].

* The values of T5 were fed to the AI to obtain the values of Ea, A, and the graph of lifetime.

REFERENCES

[1] P. Budrugeac, A. Cucos, R. Dascălu, C. Paraschiv, S. Mitrea, B.G. Sbarcea, The use of thermal analysis methods for predicting the thermal endurance of an epoxy resin used as electrical insulator, J. Therm. Anal. Calorim. (2020) 1–11. doi:10.1007/s10973-020-10156-5.

[2] G.C. Montanari, G. Mazzanti, L. Simoni, Test procedures and lifetime data analysis for electro-thermal endurance characterisation of EPR-insulated cables, IEEE Proc. – Sci. Meas. Technol. 145 (1998) 13–19.

[3] C.D.C. Erbetta, R.C.S. Azevedo, K.S. Andrade, M. Elisa, S.R. Silva, R.F.S. Freitas, R.G. Sousa, Characterization and Lifetime Estimation of High Density Polyethylene Containing a Prodegradant Agent, Mater. Sci. Appl. 8 (2017) 979–991. doi:10.4236/msa.2017.813072.

[4] Y. Xian, C. Wang, G. Wang, L. Smith, H. Cheng, Thermal Decomposition Kinetics of Core-shell Structured Wood-plastic Composites : Effect of White Mud Loadings on the Shell Layer, BioResources. 15 (2020) 2747–2762.

[5] R. Polansky, P. Prosr, M. Cermak, Determination of the thermal endurance of PCB FR4 epoxy laminates via thermal analyses, Polym. Degrad. Stab. 105 (2014) 107–115. doi:10.1016/j.polymdegradstab.2014.03.043.

[6] A. Motori, G.C. Montanari, A. Saccani, F. Peruzzotti, Analytical techniques for thermal endurance characterization of polyolefin-based materials, in: IEEE Int. Symp. Electr. Insul., 2002: pp. 375–378.

[7] A. Motori, G.C. Montanari, A. Saccani, F. Peruzzotti, Short term evaluation of the thermal endurance characteristics of polymeric materials by TA, J. Therm. Anal. Calorim. 72 (2003) 1159–1166.

[8] S. Heltzel, C.O.A. Semprimoschnig, A detailed study on the thermal endurance of Kapton HN and Upilex S, High Perform. Polym. 16 (2004) 235–248. doi:10.1177/0954008304044100.

[9] M. Moser, S. Heltzel, C.O.A. Semprimoschnig, G.G. Martin, Screening of the thermal endurance of spacecraft materials by kinetic modelling, Mater. Res. Soc. Symp. Proc. 851 (2005) 1–8.